HEALD FRAMES

THEY’RE VERY HARD.

TO WORK HARD.

RELIABILITY

First purpose of the management has always been Customer Satisfaction, with special attention to the After Sales. We place always the customer in the foreground by constantly solving and proposing targeted solutions. Our products are daily tested and overseen from our R&D and quality department within the company and in external laboratories, too, in order to improve performance and reliability day after day.

QUALITY

We are today recognized in the Textile Market for the high quality and the careful manufacture of our products. Currently, we provide with satisfaction to the biggest OEM Heald Frames & Warp Stop Motions for brands as like Vamatex, Somet, Panter, Smit, Sulzer, Itema, Sultex, Picanol, Dornier, Van de Wiele. Moreover, we collaborate with agents on foreign territories such as India, Turkey, Pakistan and we have a Sales Network extended from USAto China.

INNOVATION

The R&D department follows the market needs with special attention, with the aim of improving production processes and, above all, the functionality and reliability of the products that are daily sold all over the world. Everything is always realized closed with the Quality&Design Office for the effective compliance verification of all material and all processes in order to steadily ensure to customers the delivery of the best products.

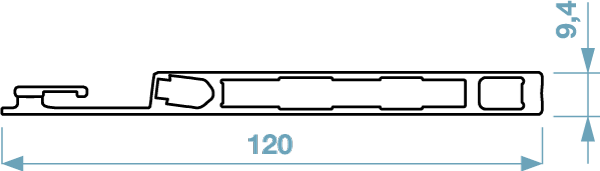

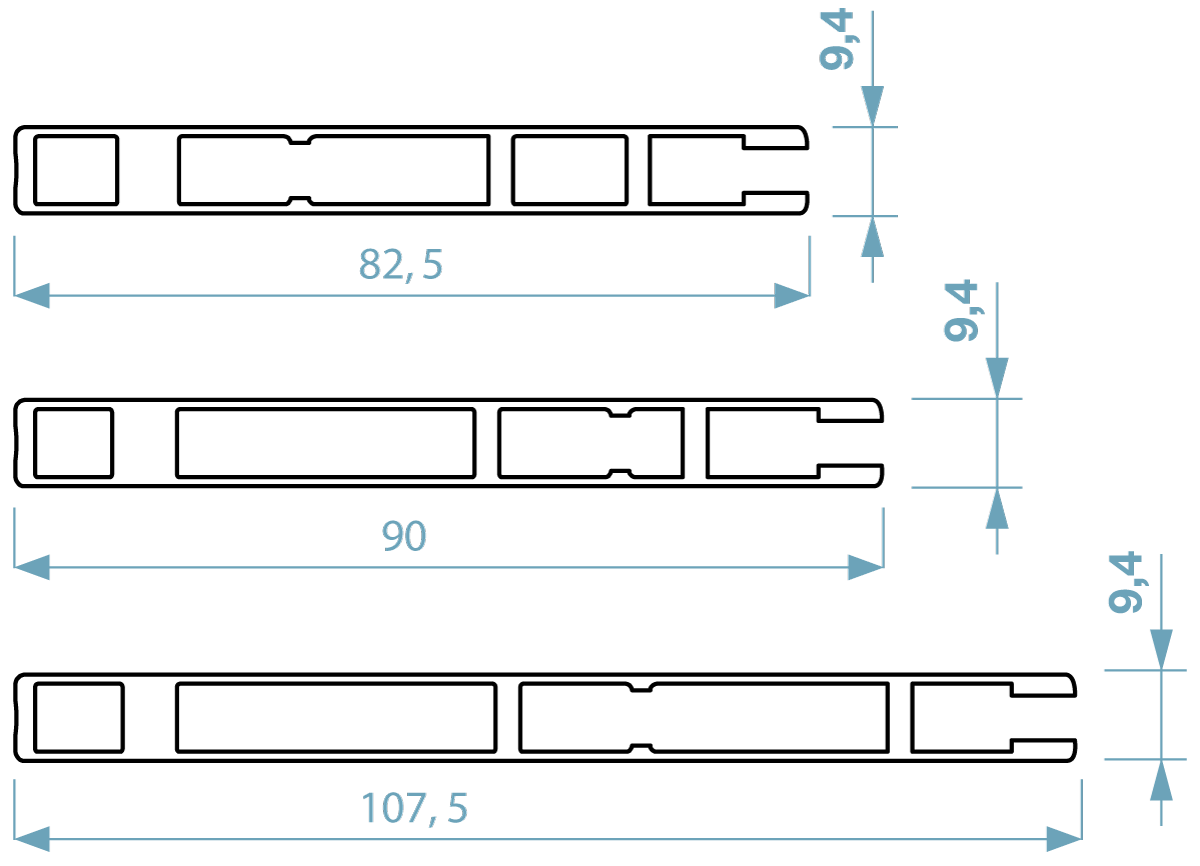

SPEEDFIX

Heald frames made of extruded aluminium alloy profile, section 120×9,4 mm. Intermediate support centrally located on heights greater than 2300 mm, with adjustable run from 80 to 150 mm. Lateral plated nickel supports available in different sections.

ULTRASPEED

Heald frames made of extruded aluminium alloy profile, section 140×8,8 mm. Intermediate supports available (if required). Lateral plated nickel supports available in different sections. Model particularly suitable for high speed weaving machines.

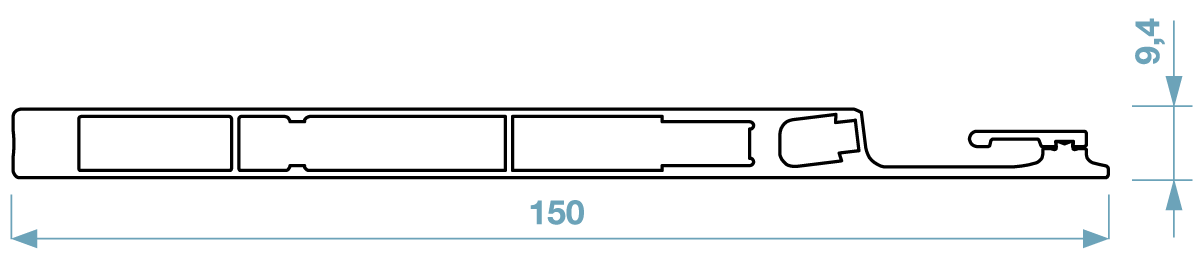

RL 150

Heald frames made of extruded aluminium alloy profile, section 150×9,4 mm. Possibility to use it without the central support. Model particularly suitable for Looms with heights over 3000mm.

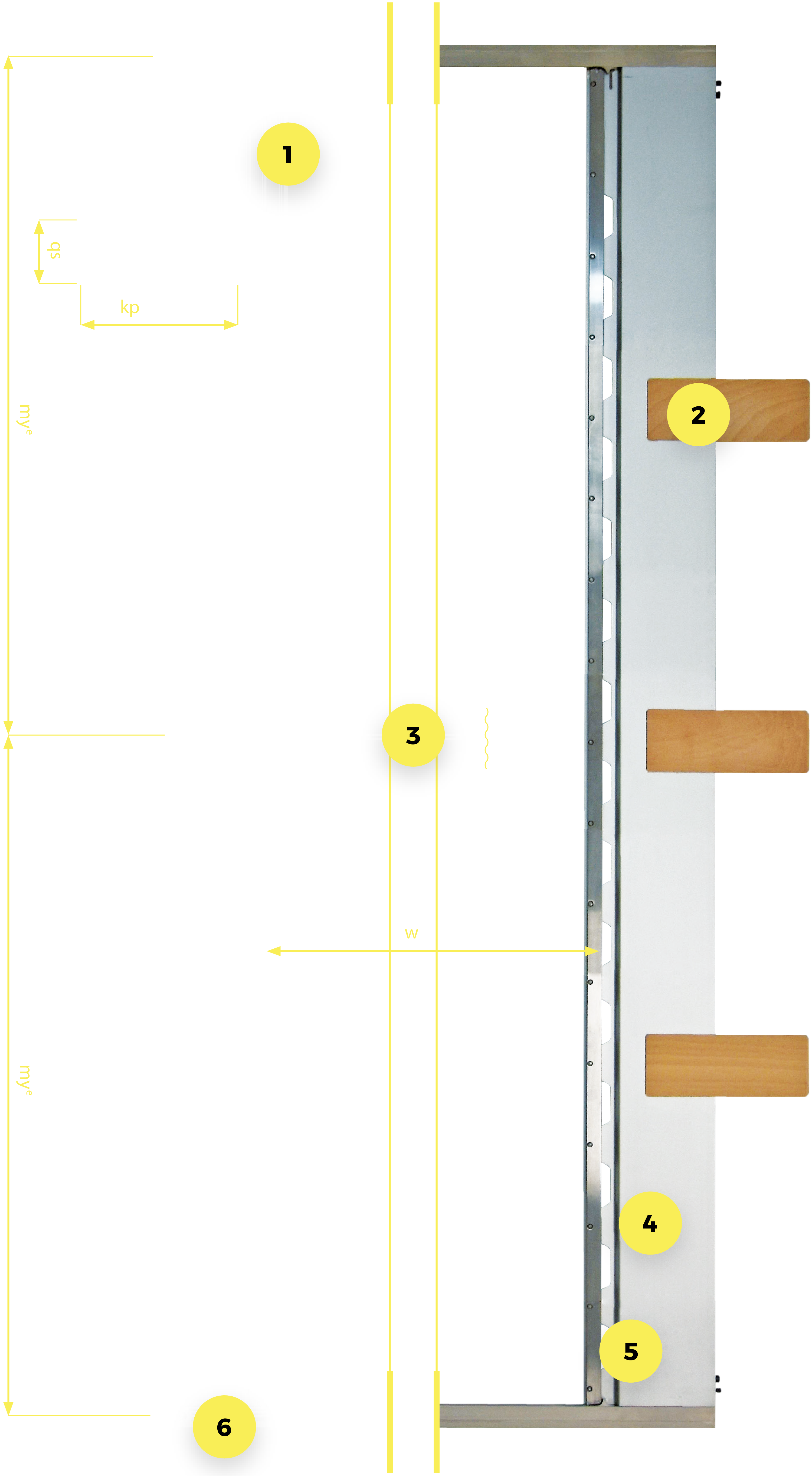

PROJECTILE

Heald frames made of extruded aluminium alloy profile with different section between upper & bottom bars. Lateral support in 6082 HB 90 nickel-plated aluminum alloy. Heald carrying rods with rounded edges not riveted on the bar but on the central plastic supports.

1) Heald carrying rods in stainless Inox with rounded edges for J or C hardened up to 45-47 HRC trough a martensitic hardening process

2) Separators made out of carefully selected seasoned beech wood, available in plastic material with low friction coefficient, too

3) Intermediate supports made of Inox, wherever needed, to stiffen the structure. It is easy to assemble, and does not require the complete unscrewing of the fixing screws and can be moved when needed

4) The frames are soundproofed by the injection of sound-absorbing material

5) Extruded bars in special, high strength anodized aluminium alloy 6005-T6 HB85

6) Lateral supports in alloy 6082-T6 HB90 nickel SP.25μ HV 550-600 with heights from 11’’ up to 30’’ (available in Lignostone, too) designed to withstand the highest speeds and connected to the bars with simple and an efficient fastening solution which allows a variable stress of the support during the weaving